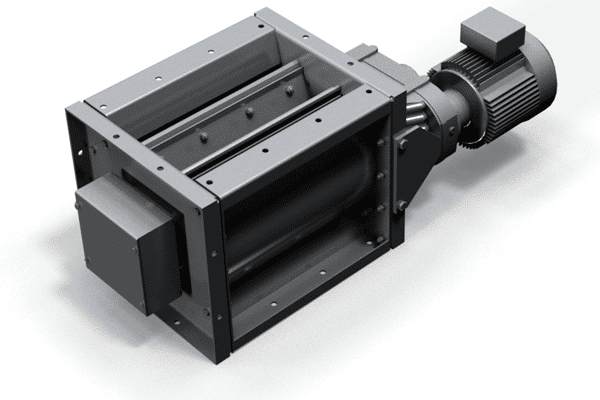

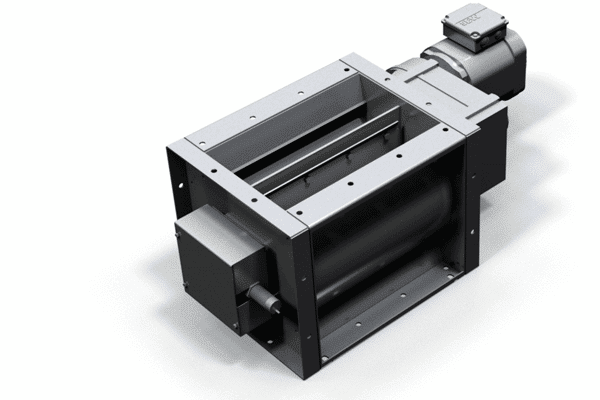

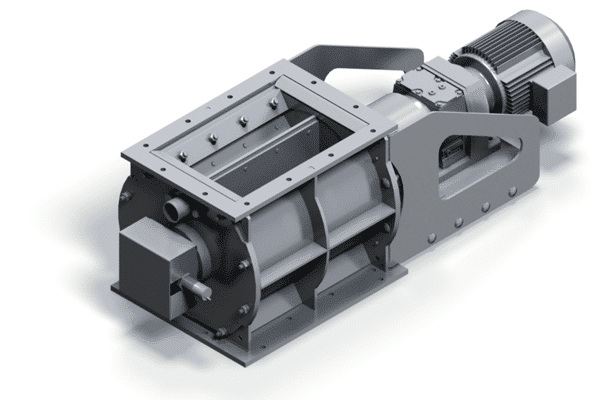

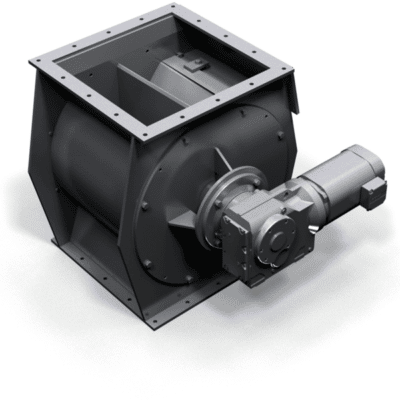

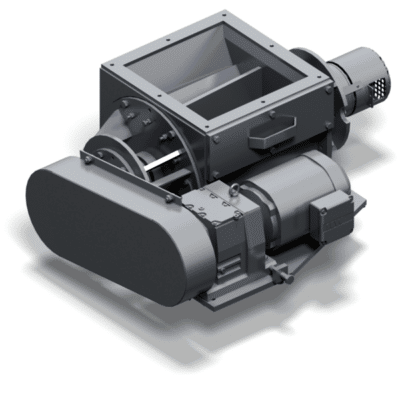

Rotary valves are used to separate plantdifferent pressures and discharge bulk materials. Here, too, the requirements profile determines the application! Our rotary valves are available in standardized nominal sizes from NW 315 to NW 2000. We pay particular attention to the nature of the material, the pressure conditions and, last but not least, safety issues such as fire or explosion protection.

Our contact persons will be pleased to help you if you have any questions about rotary valves.