Four phases mean security

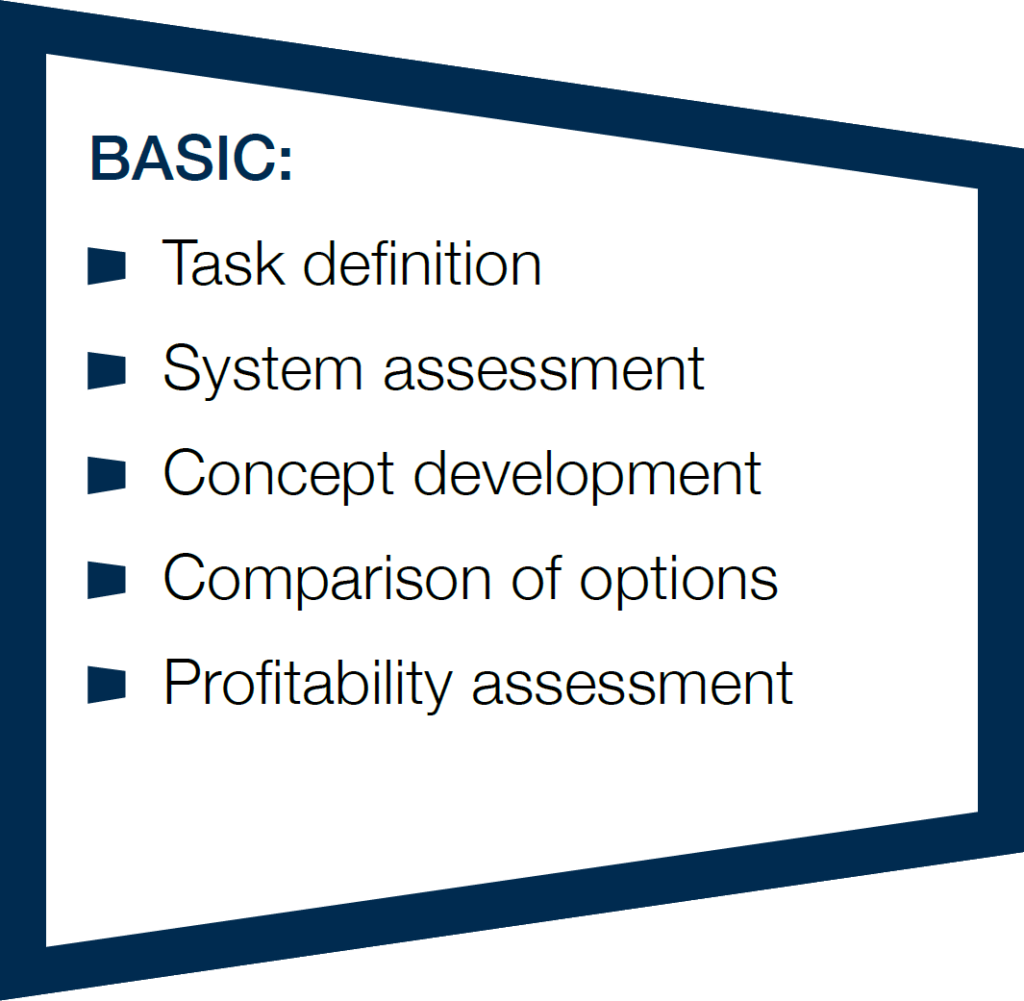

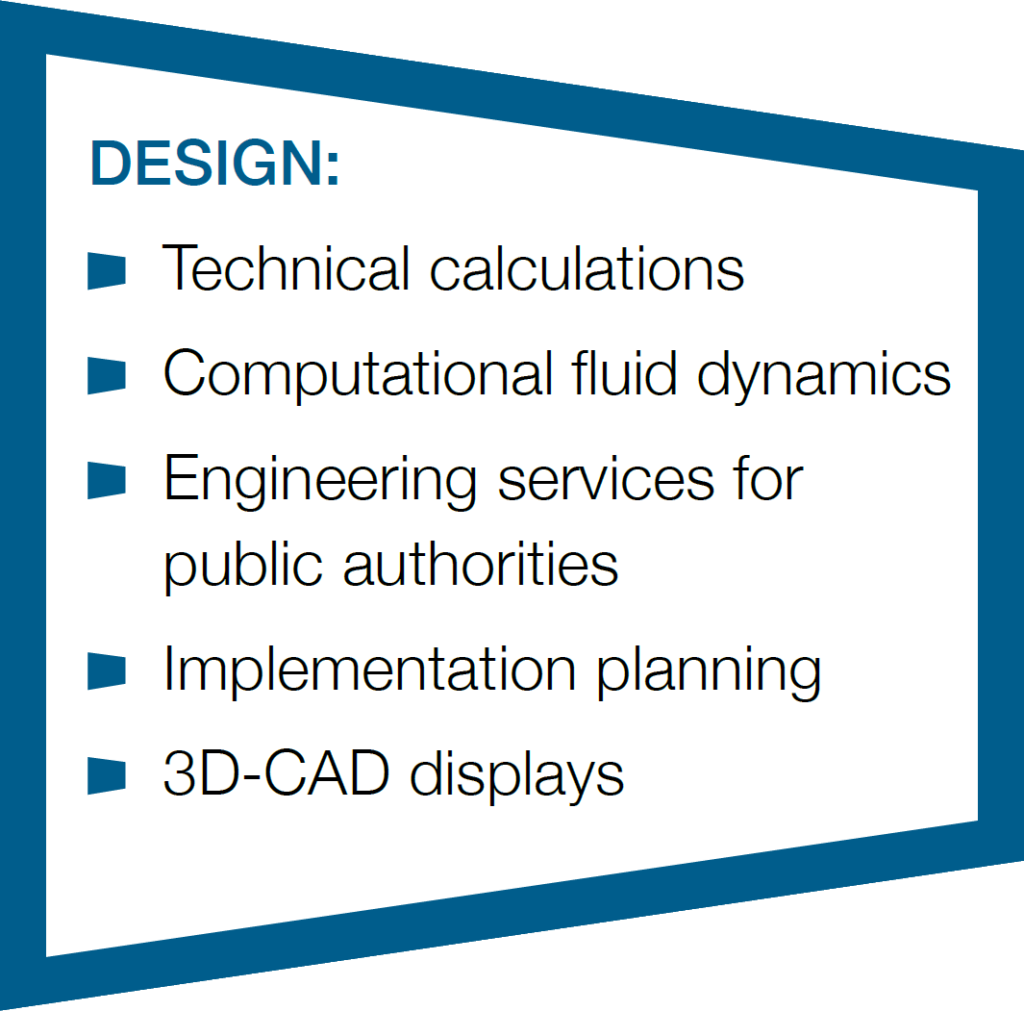

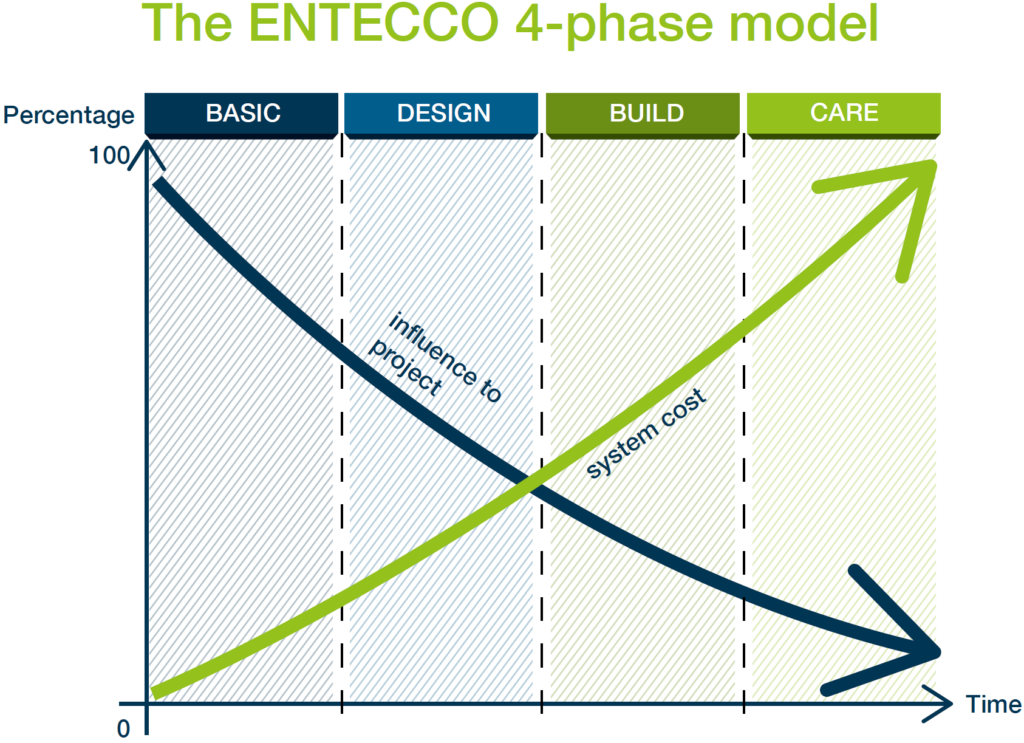

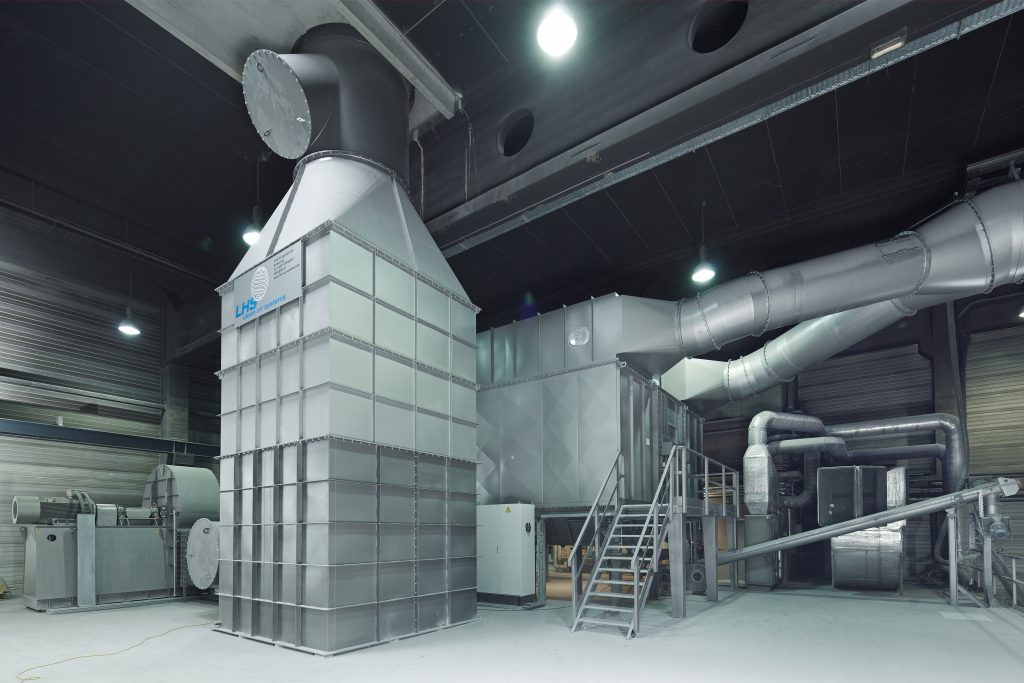

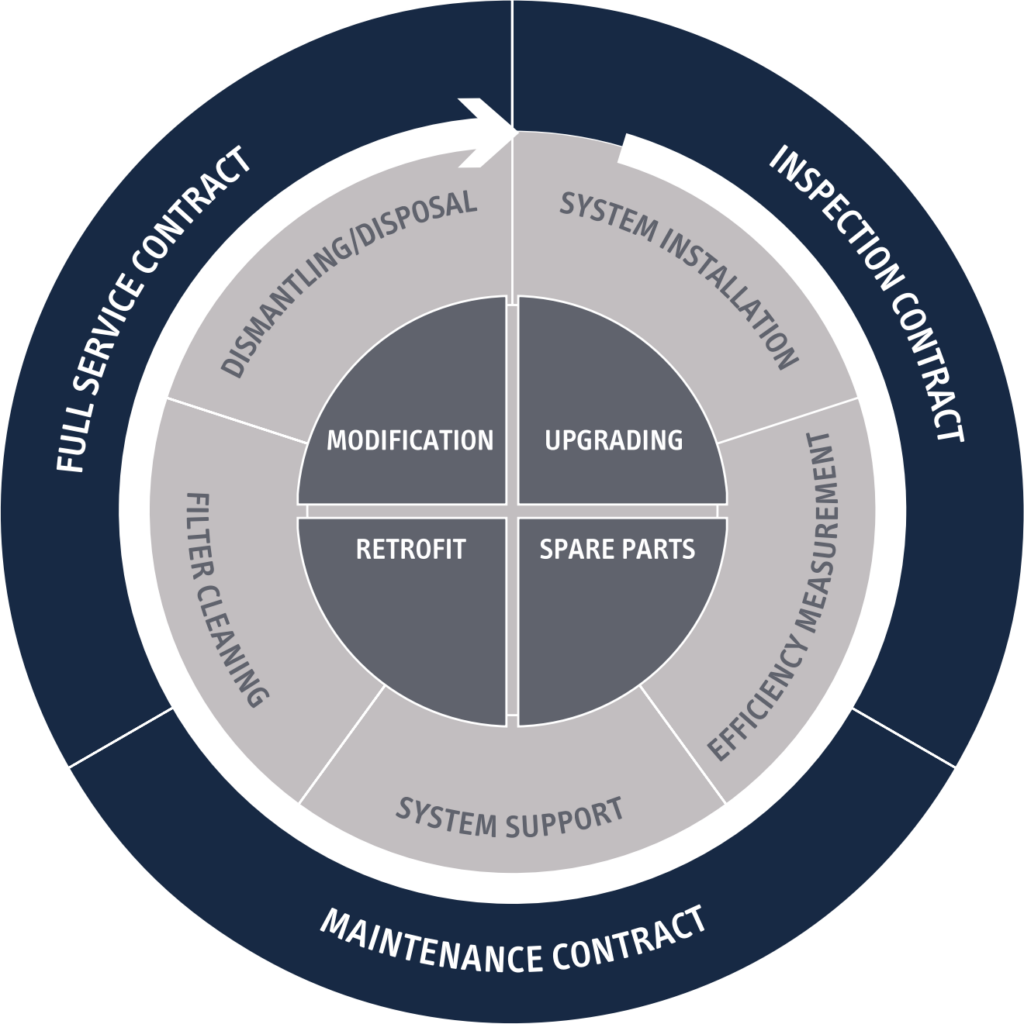

ENTECCOgroup projects are based on a tried-and-tested four-phase model: The BASIC phase is followed by the DESIGN engineering phase. Then comes system construction – the BUILD phase -, and finally there is the ongoing monitoring throughout the system’s life. We call this phase CARE.

The customer advantage becomes apparent right from the first BASIC phase. In keeping with the “flock” concept, ENTECCOgroup specialists network with one another, and pool experience from different industries, markets and university activities, thereby developing optimum solutions with lowest cost as early as the start-up phase.

This means the fastest possible implementation times. System costs are assessed early on, and subjected to an economic comparison. The aim is to achieve a highly available system with minimum cost of operation. Having everything under one roof means fewer interfaces.